As the market leader in medical-grade high-value polymer products, RENOLIT Healthcare is always looking for ways to advance healthcare solutions with the goal of increasing the health of the planet and its people. The packaging of blood and blood components is known to be one of the most critical applications of polymer medical films with new developments frequent and requirements increasing every day.

In 1950, two American doctors invented a flexible, but robust plastic blood bag that replaced the cumbersome and fragile glass containers used for infusions at the time. Since then, most plastic blood bags used worldwide have been made from that same material, polyvinyl chloride (PVC). Now, over half a century later, the healthcare industry is looking toward the more eco-friendly non-PVC blood bag to help tackle the ever-growing medical waste problem.

The components that make PVC so difficult to recycle are the same that keep the polymer supple – additives called plasticizers. Di(2-ethylhexyl) phthalate, or DEHP, is most commonly used in blood bags as it has a benefit beyond keeping the plastic pliable: it preserves red blood cells, keeping blood fresher for longer.

As the worldwide market leader for the basic materials required for the manufacturing of blood bag systems, RENOLIT Healthcare was searching for a solution that wouldn’t compromise on the quality of their products, maintain the current standard of 42 days for refrigerated blood, while also honoring the company’s commitment to sustainability and circular plastics.

That’s where Xheme came in. Xheme’s Multifunctional Additive, XMA, provides the preservative function while not affecting end-of-life options for the bag itself.

“The DEHP challenge is in discussion in the blood bag industry today, but Xheme has the solution,” said Dr. Kumar Challa, Co-Founder, President, and Chief Scientific Officer of Xheme, Inc.

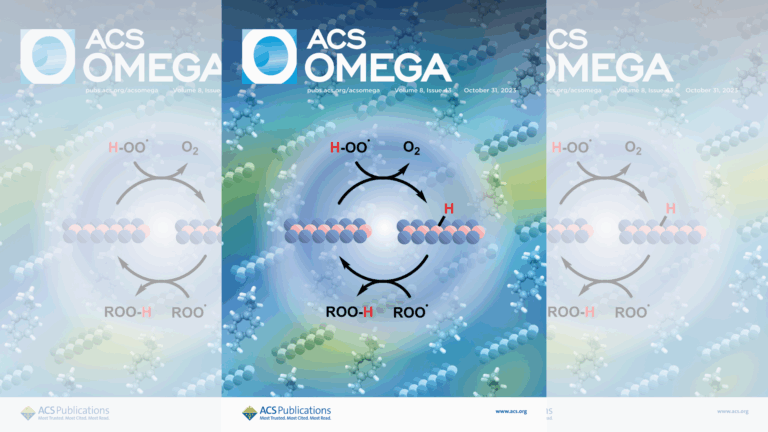

A serendipitous collaboration with Dr. Beverly Rzigalinski of the Edward Via College of Osteopathic Medicine of Osteopathic Medicine demonstrated that a certain metal oxide material prepared by Challa’s team led to better preservation of rat blood. Further investigations revealed that this material significantly reduced oxidative hemolysis — the breakdown of red blood cells from oxygen.

Challa would then go on to work with Xheme collaborator Dr. Tamir Kanias, an associate investigator at the Vitalant Research Institute, on studies showing that combining XMA in currently available PVC-DEHP bags meets or exceeds the established 42-day red blood cell shelf-life benchmark. In fact, their research showed a 20-25% reduction in red blood cell death.

Now, with RENOLIT Healthcare supplying both non-PVC and non-DEHP blood bag films, Xheme is running field tests of its XMA blood bags in cooperation with one of North America’s largest blood banks and the Canadian Blood Services. Initial results are very promising, with the XMA bags preventing oxidative hemolysis better than the control bag.

“This industry has not taken up large innovations on the non-PVC raw material side for whole blood storage,” said Paul v. Kirchbach, Manager of Business Development and Innovation at RENOLIT Healthcare. “This might be something very interesting, once we have fulfilled all required testing and regulation requirements.”

“This additive has amazing unique properties,” added Challa said. “We can fine-tune these and program the chemistry to take on all types of challenges related to plastic films.”

As more countries look toward eventually phasing out chemicals contained in PVC, Xheme and RENOLIT Healthcare Solutions will continue to drive innovation forward to find an uncompromising replacement for PVC packaging and medical equipment. This fall, RENOLIT will be doing a pilot run of XMA-EVA blood bags